Virtual Sorting System with Vision Algorithms

A virtual sorting station integrated with vision algorithms.

Project Information

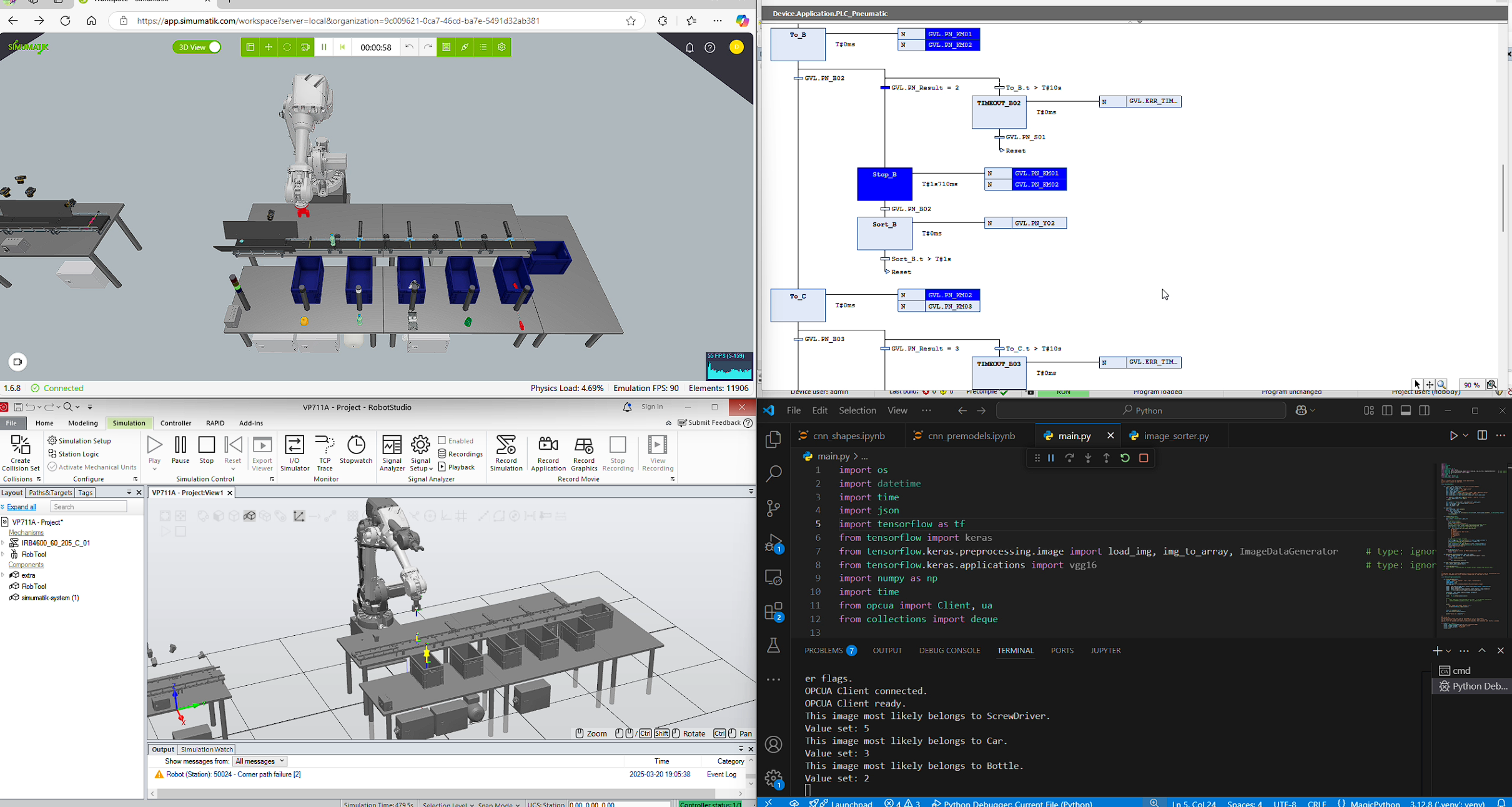

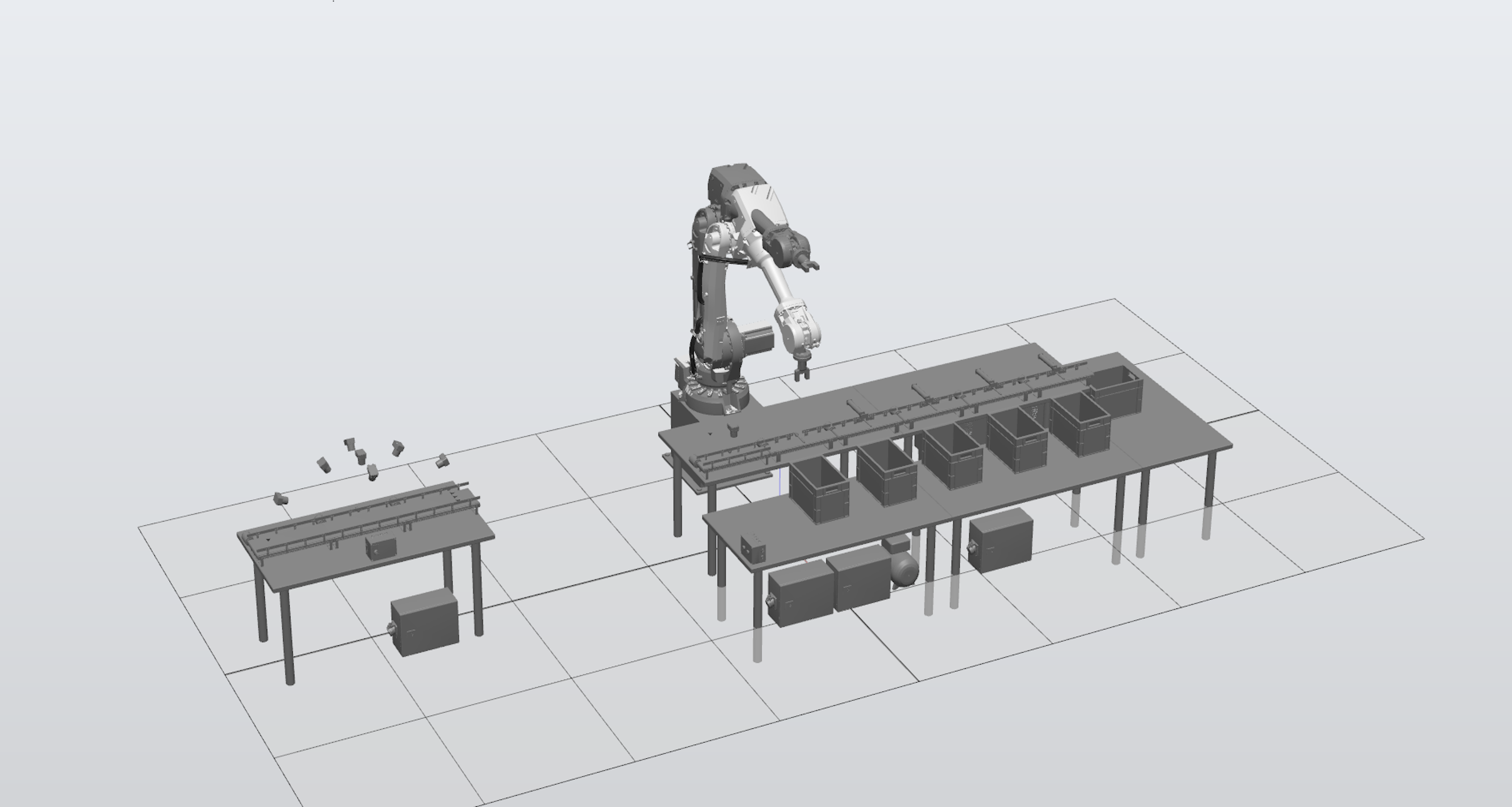

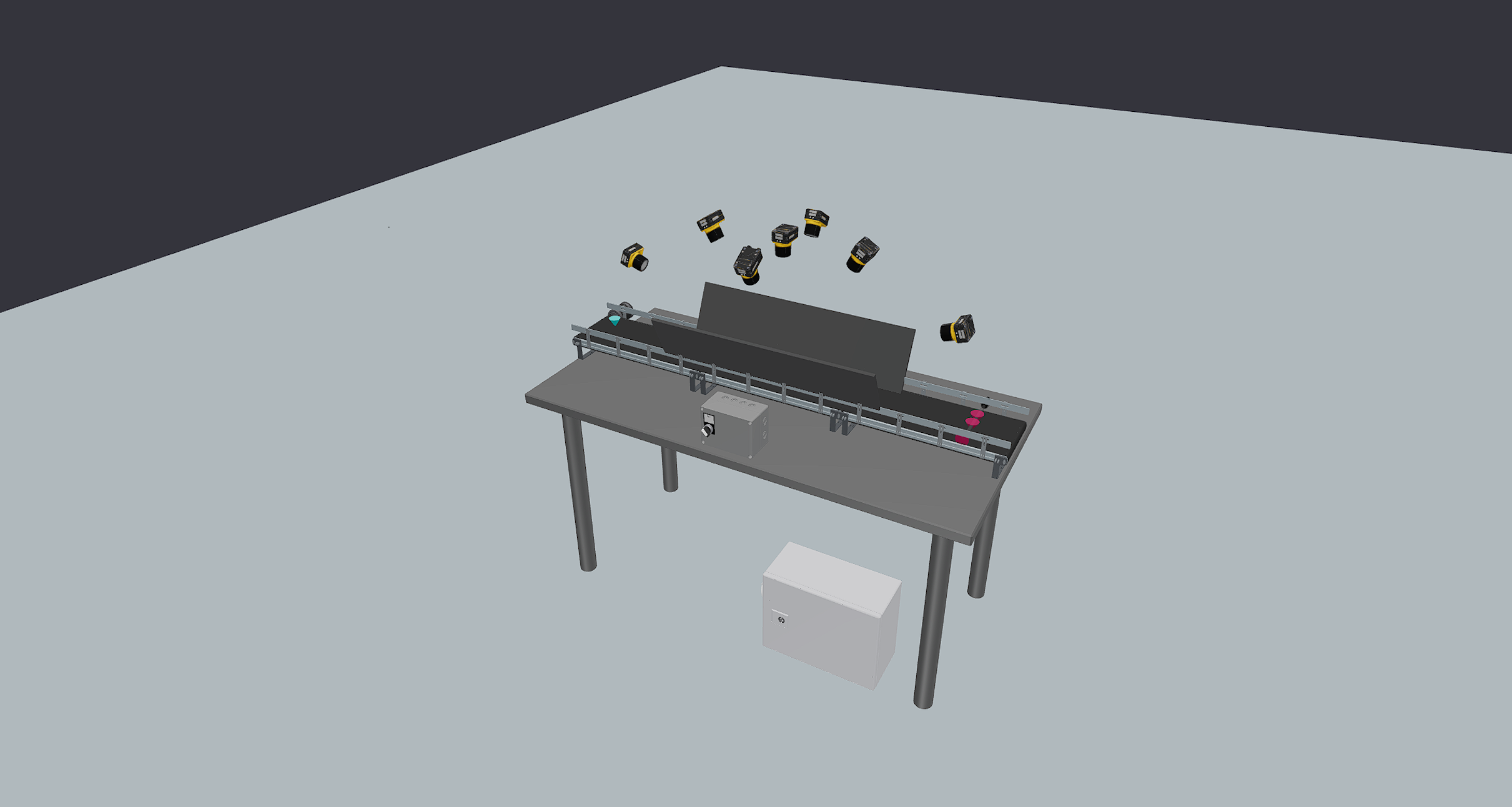

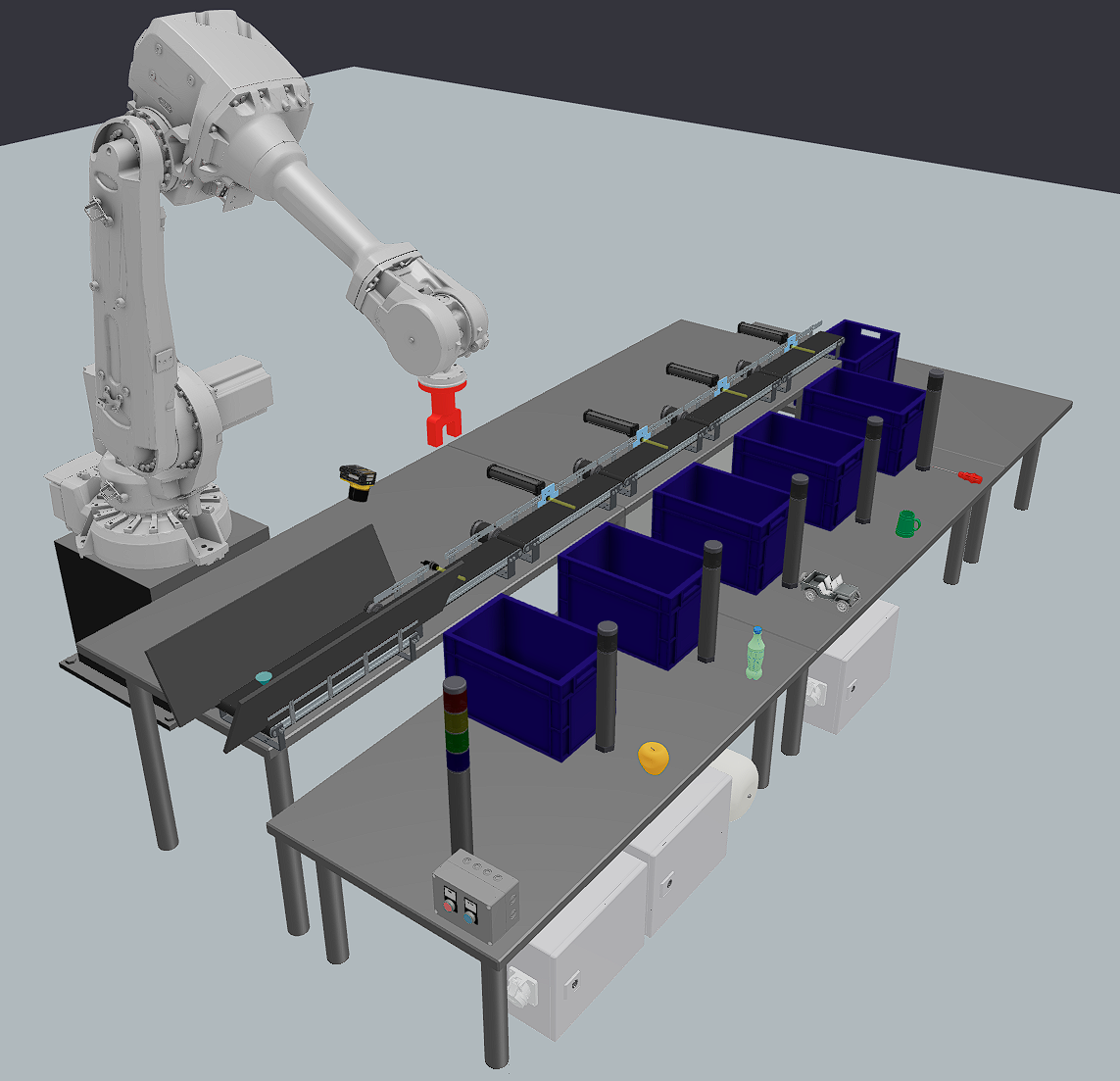

This project focused on the development of a virtual environment integrated with a Programmable Logic Controller (PLC) for automated system control. Advanced computer vision algorithms were implemented to classify products and detect defects in real time, to sort the products correctly. The solution enabled seamless interaction between vision-based inspection and automated control, enhancing both accuracy and efficiency in product handling.

Although the project was developed within a virtual environment, the technologies and systems implemented are fully transferable to physical hardware. The PLC logic was programmed in CODESYS using Sequential Function Chart (SFC) and Ladder Diagram (LD) languages, and executed on a CODESYS virtual controller. Robot integration was achieved by interfacing directly with joint axis data from the ABB RobotStudio virtual controller, where the robot was programmed using ABB RAPID. Communication and operational control between system components were established through a simulated I/O configuration, replicating real-world signal exchange. Communication between the Python-based vision algorithms and the PLC is established via the PLC’s built-in OPC UA server, with the script accessing data through nodes defined in the Global Variable List (GVL).

Project Details

| Project Name | Virtual Sorting System with Vision Algorithms |

|---|---|

| Purpose | Integrating vision algorithm like Convolutional Neural Networks to sort products in a virtual environment. |

| Tech Stack |

|

| Main Features |

|

| Development Time | ~1 Month |

| Project Type |

|

| Status | Complete |