Welding Robot

Project Assignment: Dual-Robot Coordination for Automated Welding in ABB RobotStudio

Project Information

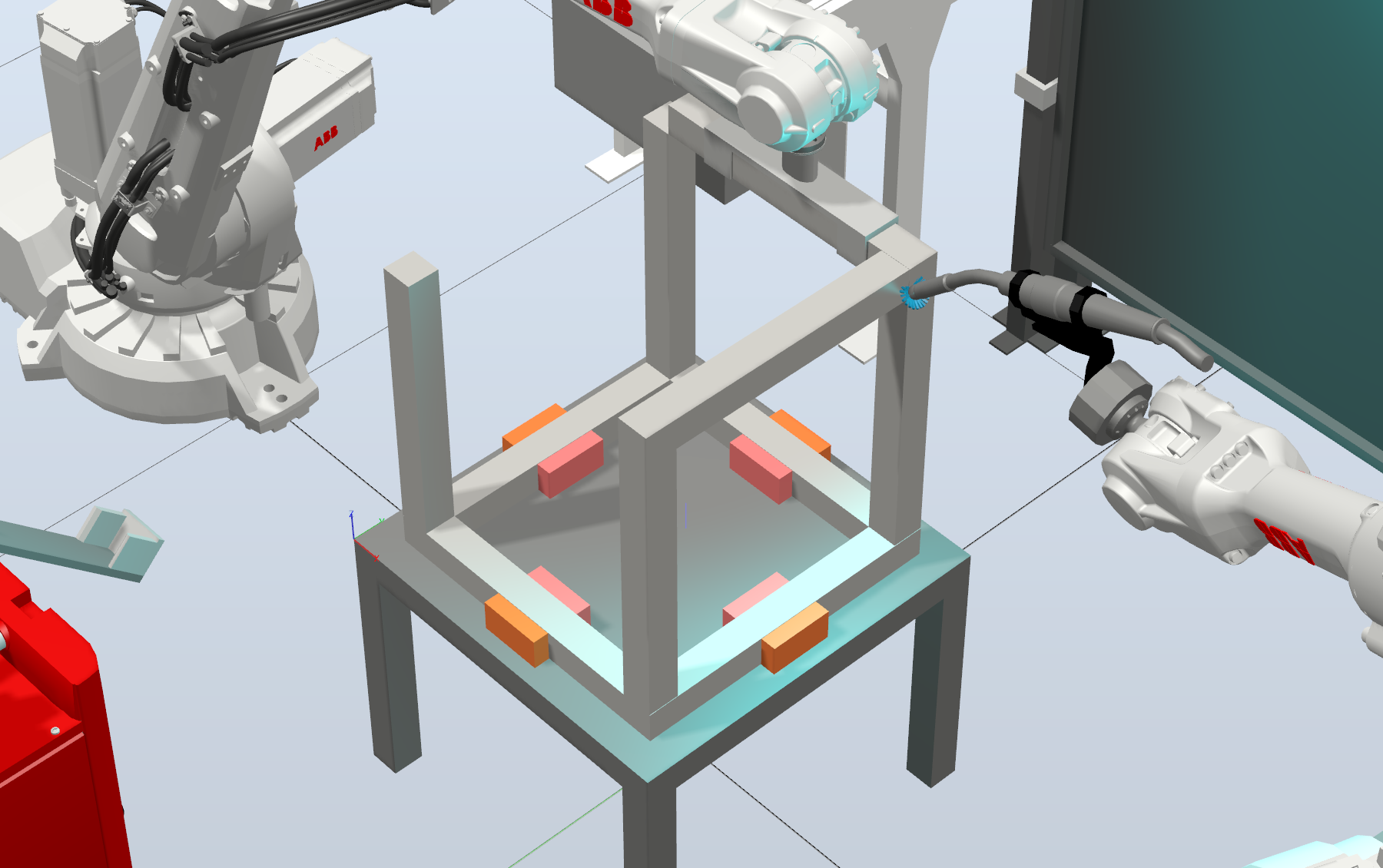

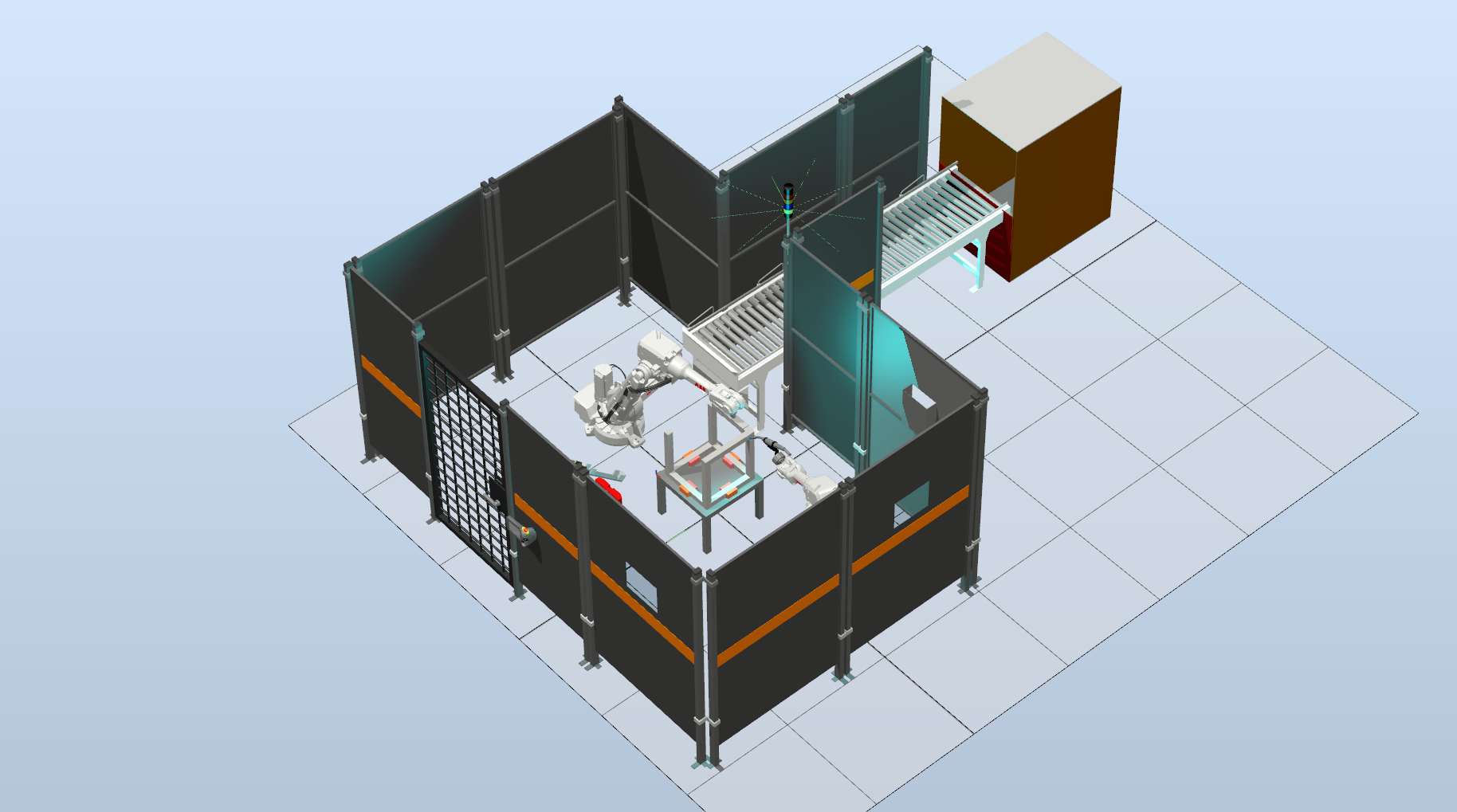

The objective of this project was to design and implement a coordinated dual-robot system within ABB RobotStudio to perform an automated welding task. The system involved the integration of two industrial robots, each assigned a specific role to accomplish a collaborative operation.

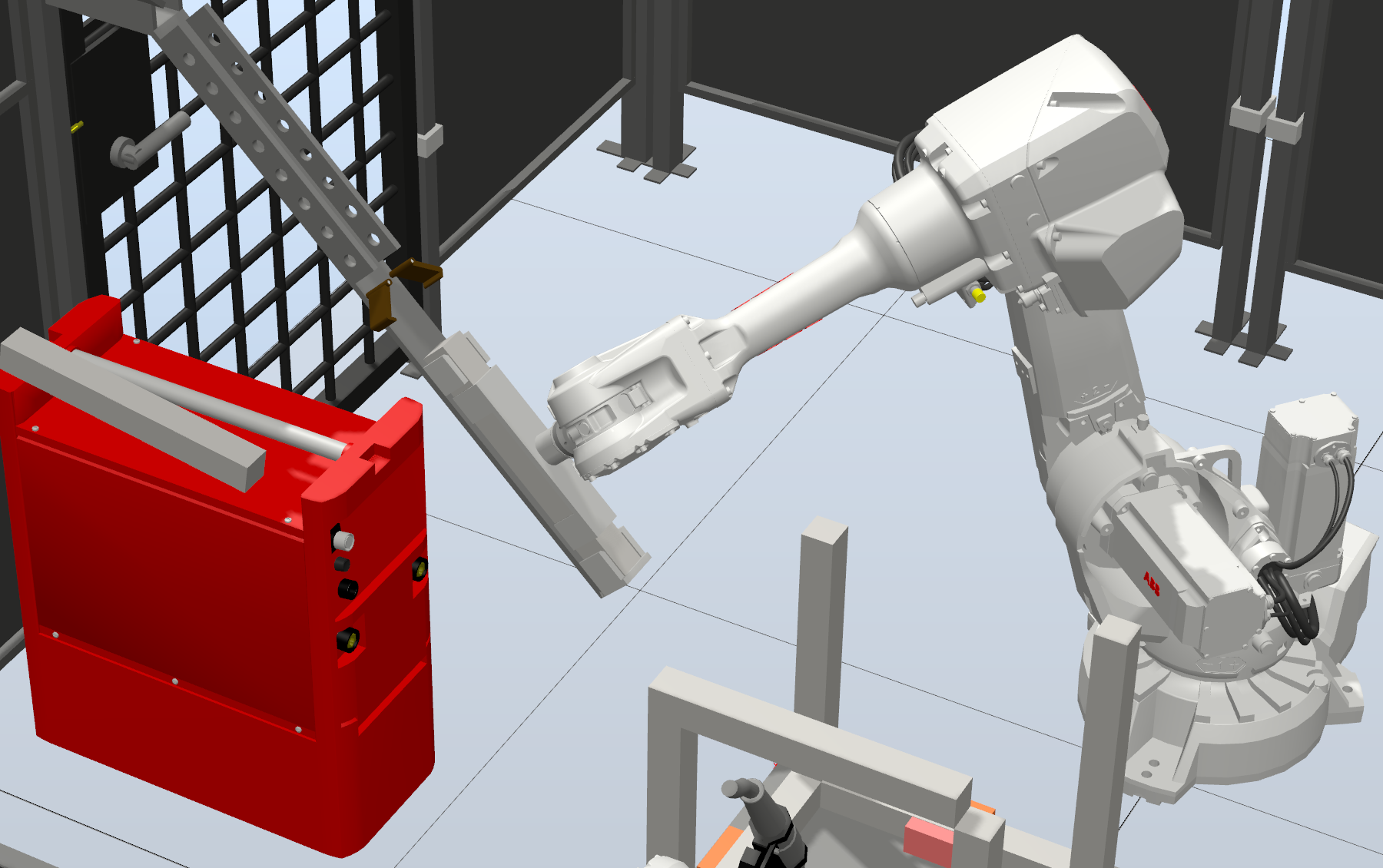

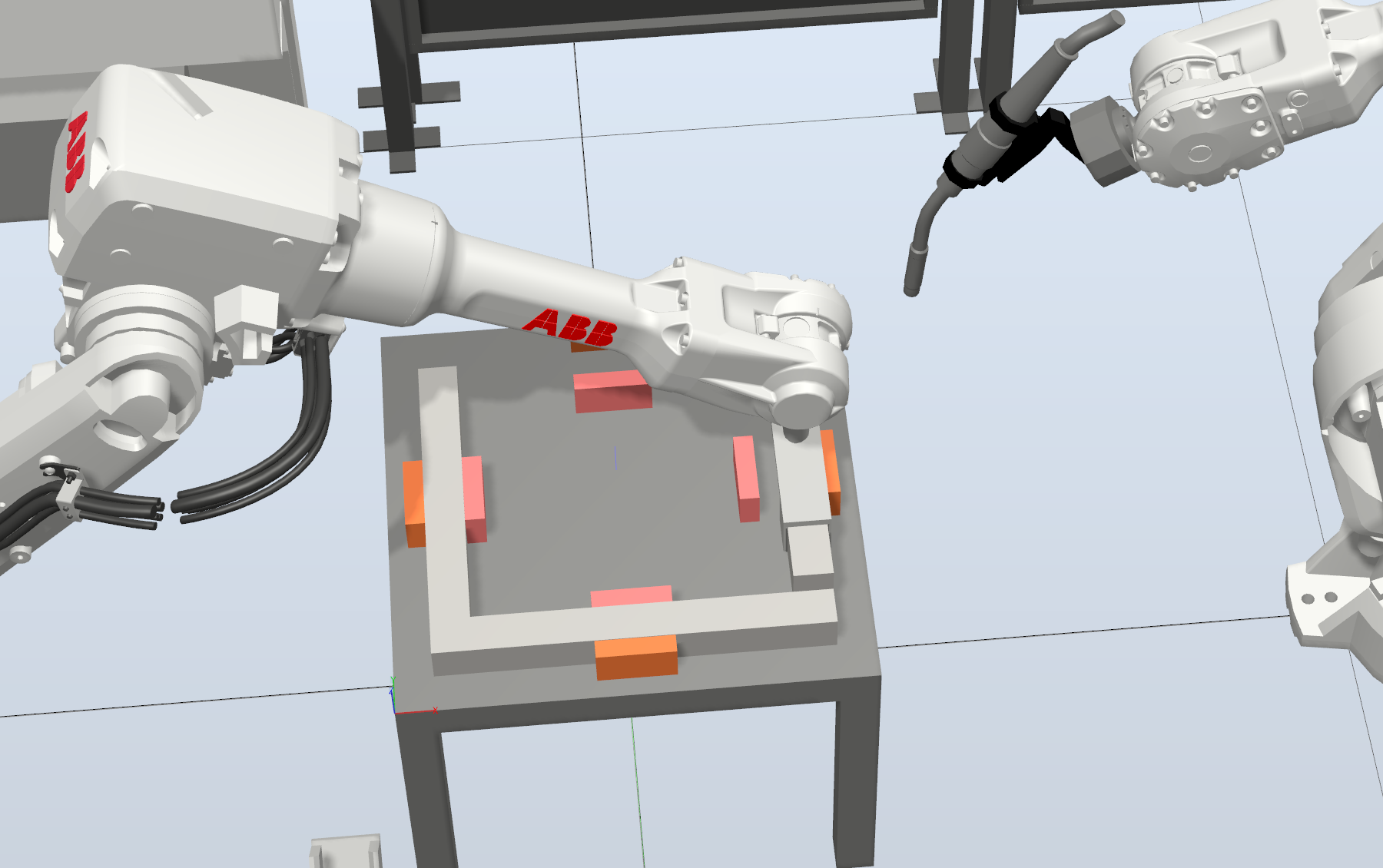

The first robot was programmed to pick up and accurately position a metal bar, maintaining it in a stable orientation throughout the process. Simultaneously, the second robot executed a precise welding operation along a predefined seam on the bar. The task required careful synchronization of both robotic arms to ensure operational safety, spatial accuracy, and process efficiency.

Key aspects of the project included multi-robot programming, tool path planning, spatial coordination, and collision avoidance within a shared workcell. This assignment provided practical experience in robotic system integration and highlighted the complexities of collaborative automation in industrial manufacturing environments.

Project Details

| Project Name | Welding Robot |

|---|---|

| Purpose | Assignment project requiring two robots to collaborate with welding a frame of bars. |

| Tech Stack |

|

| Main Features |

|

| Development Time | ~1 Month |

| Project Type |

|

| Status | Completed |